Analysis of Stress Distribution in the Photopolymerization

of Resins and Subsequent Release of Tensions after Hygroscopic Expansion

Replacing traditional mechanical methods of retaining restorative materials

are currently being used conservative methods of adherence. The concept

of large preparations is being abolished and replaced by less invasive

preparation, with the adhesives methods. You can find bonding agents that

adhere to various substrates (dentin, enamel, amalgam, metal and porcelain),

being that the adhesiveness to each is distinct.

When using a resin to fill a preparation, this can be cured or not, and

that healing can be followed by a contraction of the material. The contraction

of a resin is a mechanical property. When applying restrictions on the

movement of the material on contraction and phase change, stresses appear

in it. Those tensions will remain in the material after its polymerization

and may be understood as residual stresses. However, some of these tensions

can be released by hygroscopic expansion that occurs in the resin when

it comes into contact with water.

This study aims to evaluate the residual stresses developed in the polymerization

of photo-activated resins, using different filling techniques, and their

subsequent reduction during hygroscopic expansion.

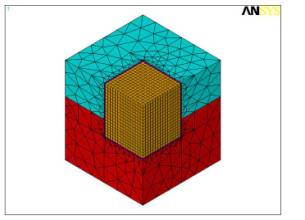

Aiming to better understand

and model the proposed problem, we decided to fabricate a three dimensional

model of the cavity preparation. Taking

into account the effect of contraction of the resin is less significant

in a region away from the preparation, was adopted by isolating a portion

of biomaterials in the region near the contraction in order to reduce

the size of the model. The figure below illustrates the model with the

three

materials considered: enamel (blue), dentin (red) and resin (orange).

Model

Figure 1

This model has a highly non-linear character. There are two

types of non-linearity: the non-linearity introduced by the steps of

filling (geometric non-linearity) and the non-linearity from the state of

the interface,

ie, if this is breached or not.

TEAM: Estevam Barbosa de las Casas, Rodrigo

Lambert Or éfice, Elissa Talma and João Batista Novaes Júnior.

![]()